Raytek

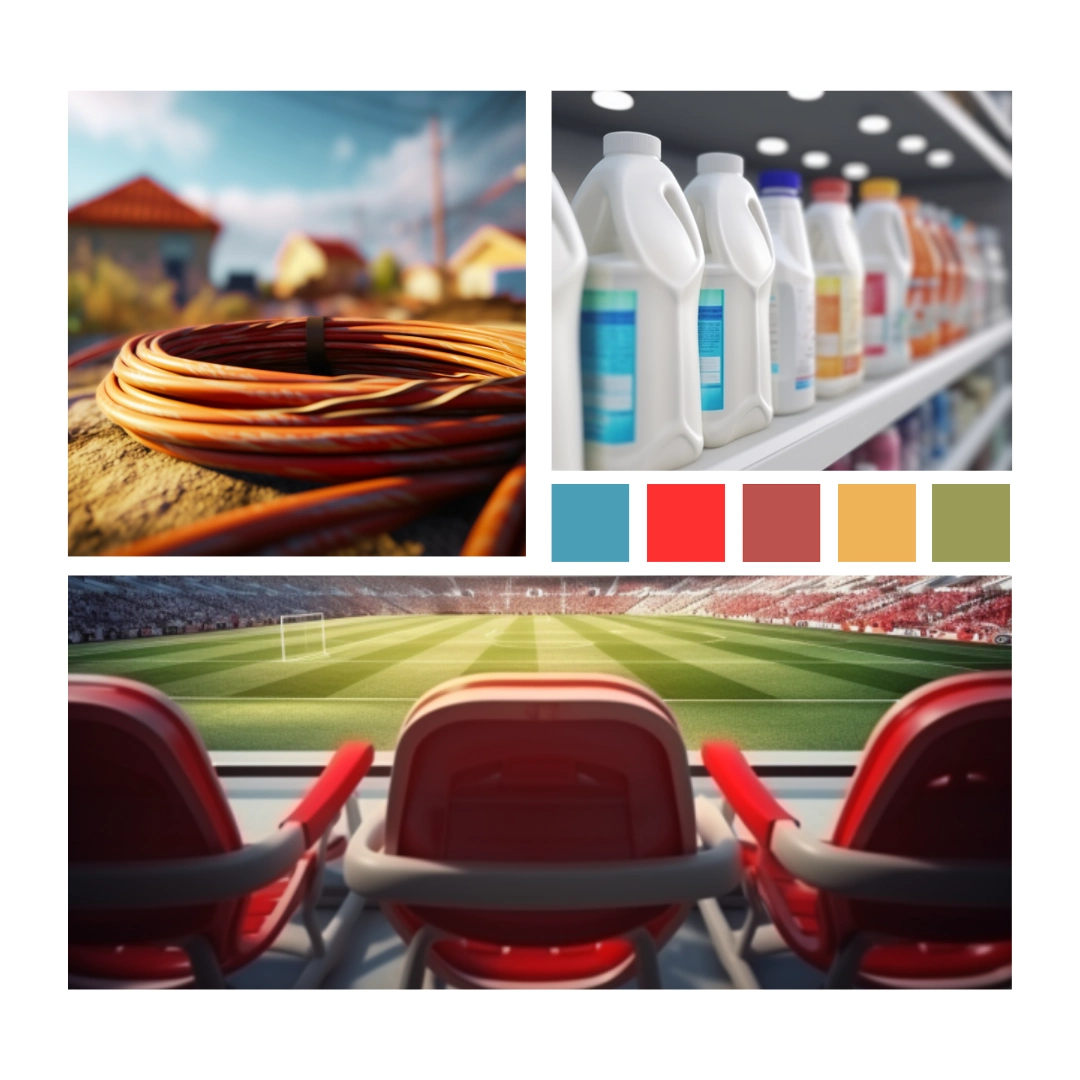

UV protection, warping, breathability… These are some of the obstacles our customers face in the contemporary market. Formulated with meticulous and careful studies, Raytek masterbatches are forged in our laboratory to give a concrete answer to these challenges. The ingredients that make up our unique recipes? A lot of chemistry and physics research and a pinch of love for science experiments.

Litescreen

Highly perishable products, such as vitamins and nutrients, protect us daily. But who protects them? A well-designed packaging is not enough: the same light that, filtering through the container, penetrates the content can be extremely harmful. It can destroy the properties of substances with disastrous effects. Then, how to protect products from UV rays damage? The Litescreen line has been specifically designed to interfere with the light waves of the visible and ultraviolet spectrum, in order not to let the radiation filter through. Thanks to the color technology, it is possible to obtain UV protection and to defend the contents inside the pack with just a single layer of plastic.

Shelligent

How to handle plastic warping? This is the challenge that those who work on precision product design projects constantly face. In fact, the choice of pigments and additives can determine the distortion of the plastic after the exposure to heat. If the shrinkage is not equal during cooling, it causes dramatic deformation. This causes the impossibility of joining the item with other components of the product, or the aesthetic alteration. Shelligent masterbatch line includes low-warping additives for plastics, called nucleating agents, to control dimensional stability.

One Pack

All in one. Everything you need concentrated in a single masterbatch granule, where the necessary elements are compressed together in a super concentrated and super functional product. Here the embedded additives can work synergistically with the pigments contained in it. It is also possible to obtain variants of the same color with different combinations of additives for plastics. Easy, don't you think? There will no longer be the need to separately weigh colors and additives to add to the mixture: we have already taken care of it.

Phosphore

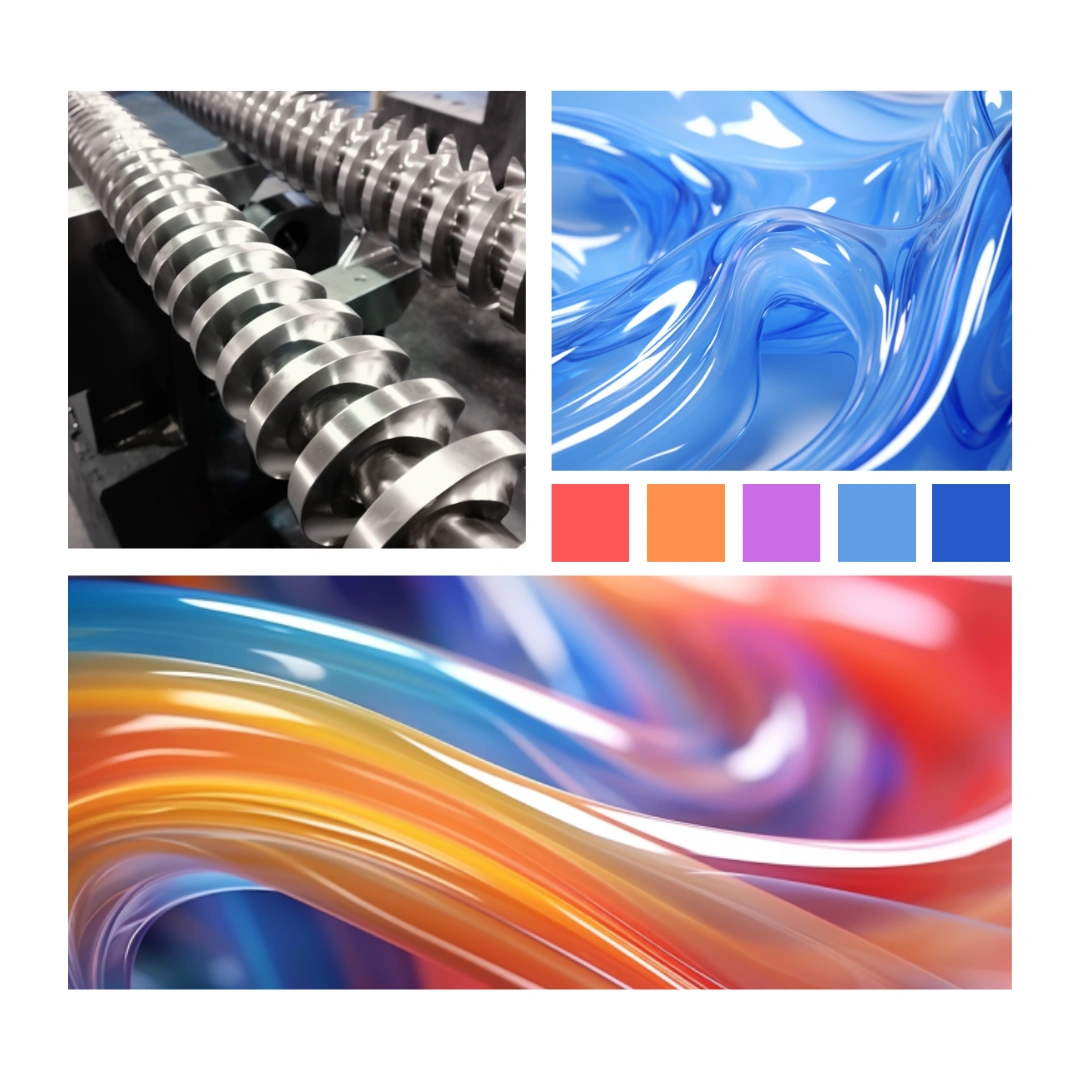

The color masterbatches of the Phosphore line employ light radiation to activate their peculiar properties. The products are divided into two categories: phosphorescent and fluorescent. The phosphorescent colors release gradually the accumulated energy over time. In other words, they glow in the dark after receiving light. On the other hand, **fluorescent colors **for plastic when they receive energy, re-emit it with a different and more intense wavelength than the original one. This enhances new colors that stand out to the human eye. The amazing effects can surprise even the most difficult audience.

Over

The constant interaction between plastic and organic matter can be harmful sometimes. An example is given by the personal hygiene sector, where plastic films in direct contact with the skin of delicate body areas can cause the onset of medical complications. The same is true in agriculture, where plants and soil risk suffocating or developing mold. Then, is it possible to make plastic breathable? We found the answer in our line of masterbatch Over. This is specifically designed for plastic film: it contains materials suitable for the microperforation of the product. Thanks to this **air permeability **system, the film produced results to be breathable and still resistant. Seeing is believing.

Cleaner

Our process Cleaner: it was initially developed for internal use to optimize production. With its action, it is possible to notice better **cleaning of extruders **and machinery in general. This step is fundamental in the companies dealing with colors, to avoid contamination. Indeed, even the slightest residue trapped in blind spots can leave visible residues, considerably worsening the productivity. Cleaner aim, therefore, is precisely to improve cleaning times, in the advantage of production efficiency, and to reduce industrial waste, with a consequent decrease of disposal costs.

Discover Our Masterbatch

Enter the Gaypa world and explore all our products for coloring plastic and our projects with technical additives and more. You might find just what you're looking for.